What are food dosing pumps?

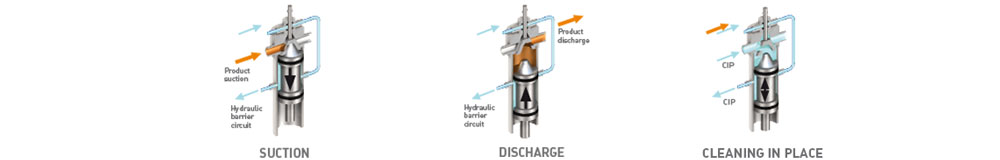

Dosing pumps are small positive displacement pumps, designed to offer a precise flow rate by drawing a specific amount of liquid into a chamber to be injected into another container or substance. They are usually powered by an electric motor or air actuator, and controlled by an external control system or an internal pump controller, which allows for minimal loss.

How dosing pumps work?

Where are dosing pumps used?

Dosing pumps are prevalent across the food sector. These pumps are highly appreciated by convenience food and bakery manufacturing plants for their capacity to dose fluids with particles with a high level of accuracy at high flow rates. They can also be employed in the handling of dairy products, sugar and starches as well as meat, fish and animal food.

For food applications, dosing pumps are integrated into dosing or filling systems. These are designed to reduce waste, making use of their highly efficient inline injection. Dosing pumps can handle a range of fragile fluids with solids (up to 48 mm) which makes them suitable for use over a number of industries.

What are the benefits of PCM dosing pumps?

- Capable of dosing precise amounts and minimising waste

- Cleanable in place (CIP)

- Dosing pumps are extremely adaptable to your existing industry’s facilities

- No emulsion, no aeration, no shearing: respect of the pumped product

What are the maximum performances of PCM dosing pumps?

- Pressure: up to 20 bars

- Speed: up to 60 strokes /min

- Accuracy: +/- 0.5 %

- Particle sizes: up to 48 mm