The fluid handling expert

Your challenges are at the heart of our concerns. Therefore PCM is at your service to create innovative products and services. Innovation and creativity have guided PCM’s expansion for 80 years, and all new projects aim to make our pumps and systems more competitive. With constant concern for market needs and evolutions, our Innovation department develops new, highly effective fluid handling solutions and optimizes existing ones.

Innovation is in our DNA

Our approach to pump and pump system design is driven by:

Controlling Life Cycle Costs – LCC

LCC (Life Cycle Costs) analysis helps you find the solution for your requirements. It has a positive impact on competitiveness, cost savings and operational profitability.

By determining the Life Cycle Cost (LCC) of a pump or pumping system, it is possible to compare design alternatives to find the most cost-effective long-term solution that best matches your needs.

LCC is not just for new pump acquisitions. Applying LCC to existing pump systems can yield dramatic results, because often they have not been optimized since their installation, and pumping tasks change over time. Studies estimate that 30-50% of the energy consumed by pump systems could be saved by changing equipment and/or control systems.

Finally, LCC can help you comply with current and future environmental regulations by increasing energy efficiency and minimizing the environmental impact of equipment disposal. Our wide range of Positive Displacement Pumps offers you a greater level of choice when trying to meet sophisticated requirements.

Reducing environmental impact – Eco design pumps and systems

Today, PCM has unmatched experience in the field of Eco-Design for pumps. PCM Eco-Design aims to reduce the environmental impact of a solution during all the stages of its life cycle, from suppliers and manufacturing through to decommissioning.

To measure the environmental impact we look at resource consumption, emissions, waste treatment, disturbances (e.g. vibrations, noise), energy consumption.

In practice, eco-designed products require fewer raw materials to manufacture and are comprised of fewer parts. They are manufactured in our ISO-14001 certified facilities.

A lighter, more compact pump requires less energy to transport. During its operational lifetime the pump has higher energy efficiency, the parts last longer, service times are shorter and production losses are lower.

At the end of its life, an eco-designed pump has fewer parts that require disposal. There are no hazardous materials that need treatment, and PCM provides a parts recycling service during dismantling.

Customer-centric approach – Flow Technology Center

Every solution starts with the customer. Our Flow Technology Center exemplifies our customer-centric approach to pump design. Instead of inventing pumps and trying to adapt them to your needs, our Flow Technology Center starts with the fluids to be handled in order to find the best pump design.

Computational Fluid Dynamics

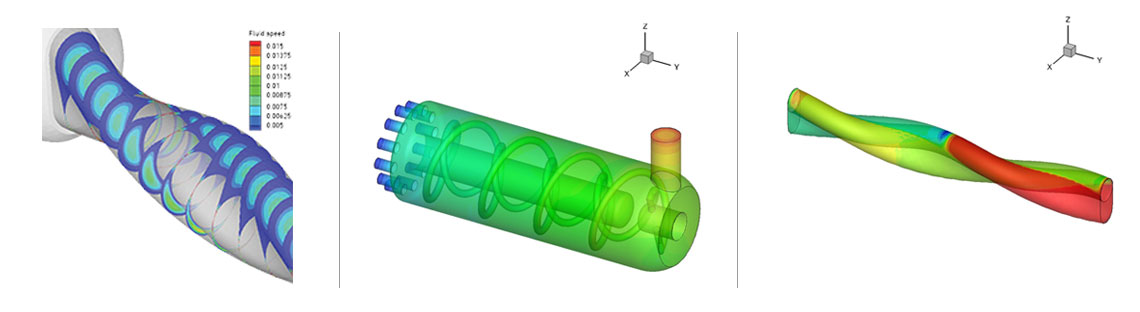

The use of CFD (Computational Fluid Dynamics) nowadays is a very powerful and robust tool to model fluids related phenomena. The continuously growing need, arising in the industry, to solve in relatively small time interval and with high accuracy hydraulics problems has led to the great development of this domain in the last decades.

Numerical simulations are carried out in the R&D department of PCM which allow computing the flow field through the volumetric pumps produced by PCM for many applications including Oil&Gas, Food and Industry. The prediction of the hydraulic behavior of the pump at the preliminary stage of the design, as well as in the validation process of the final product is one of the main goals of these calculations.

Examples of numerical simulation using CFD modeling performed in the new PCM Hycare™ PCP model and PCM Dosymix™ mixer is shown in the next figure.

Fluid testing

The Flow Technology Center provides a full range of fluid testing services. Our experts analyze the rheometric, mechanical and chemical properties of the products to be handled in order to determine the most suitable pump and installation. In particular, fluid testing makes it possible to match fluids with the most suitable elastomer, coatings and materials for parts.

Elastomers

The Flow Technology Center selects the most suitable elastomer based on the results of the fluid testing. Picking the right elastomer plays a crucial role in determining the lifetime and performance of pumps with an elastomer chamber or stator.

Modeling & prototyping

Before incurring the expense of manufacturing and installing a custom pump, the Flow Technology Center performs fluid simulations using our sophisticated hydraulic modeling systems. This enables us to develop the best prototype in the shortest possible time.

The Flow Technology Center then conducts on-site prototype trials and validation before manufacturing the final production models. After installation, the Flow Technology Center strives to learn as much as possible about the performance of our solutions throughout their lifetime.

An expertise serving offers at the leading edge of technology

This expertise makes us uniquely qualified to offer you the most advantageous total cost of ownership (TCO).

Progressing cavity pumps – PCM, the original manufacturer

PCM has inherited the drive and ingenuity of our founder, René Moineau, who in 1930 published a pioneering dissertation that paved the way for the Progressing Cavity Pump (PCP).

In a progressing cavity pump, a rotor turns inside a stator, producing a steady flow based on drive speed. This makes it possible to match a PCP with virtually any application. Progressing cavity pumps are ideal for pumping viscous, particulate, abrasive and fragile products. They are equally suited to applications that require artificial lift, such as oilfield applications.

Changing the geometry – or shape – of the rotor governs the pump’s output. Therefore, a PCP can be designed to deliver precise and continuous flow of even the most difficult materials.

Other technologies

- Peristaltic “hose” pumps: Our Delasco™ pumps are very easy to maintain

- Dosing pumps – Highly accurate Dosys™ pumps

All our pumps are available on turnkey skid systems that simplify and accelerate the integration of PCM solutions into industrial processes.