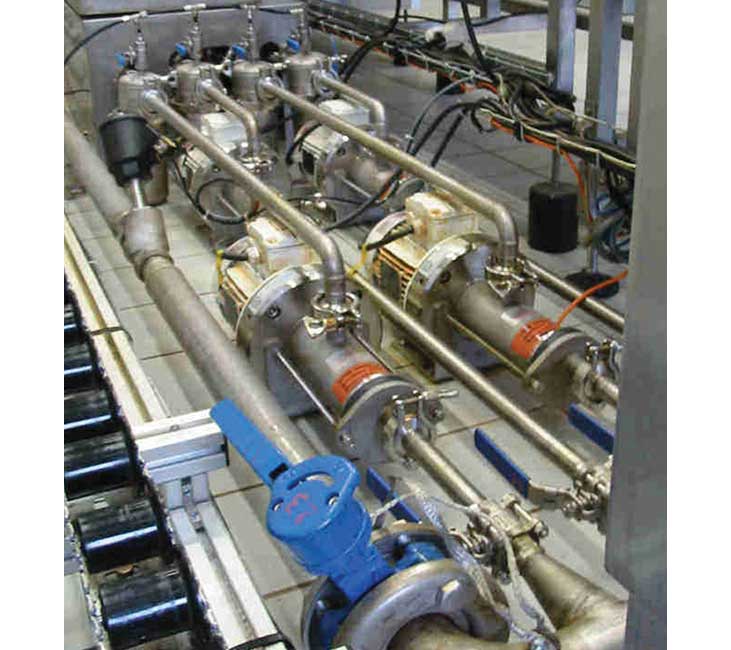

PCM EcoMoineau™CF floating stator - small food grade progressing cavity pump

As one of most compact progressing cavity pumps available today, the PCM EcoMoineau™C floating stator pump can handle a wide range of fluids with varying viscosities and solids. It provides good suction lift and can tolerate run dry. It offers low Life Cycle Cost, thanks to simple design, cost-efficient maintenance and reduced weight. The pump can be rapidly dismantled for Cleaning Out of Place (COP) in food applications.

PCM EcoMoineau™CF floating stator pump is based on the “Moineau™” progressing cavity pump principle.

PCM EcoMoineau™CF floating stator pump is ideal for small space requirements. Instead of the connecting rod, used on the conventional progressing cavity pumps, this PCP is designed with a floating stator in elastomer without frame. The flexibility of the stator allows the rotor to rotate eccentrically, as the rotor is directly connected to the drive. The pump body is consequently shorter.

In many cases the PCM EcoMoineau™CF floating stator equipped with a frequency inverter can be used as a dosing pump. It is an advantageous replacement for traditional dosing units for viscous, articulate and abrasive products. It’s compactness and robustness makes it particularly suitable for integration in machines and systems.

Discover our new PCM food pumps and systems catalogue here.

Benefits

- Compact size

- Reduced weight

- Conception dedicated to food industry with COP (cleaning out of place)

- Dosing pumpwithout pulsations

- Simple and rugged construction in stainless steel

- Low life cycle costs

Performances

- Maximum flowrate: 6 m3/h

- Pressure: 4 bars

- Maximal temperature (in continuous operation): 80°c

- Particles size : 6 mm

- Accessories : pressure sensor, dry running protection

- Options : trolley, by-pass and/or safety valve, automatic level, flow rate and pressure controls.