What are the advantages of industrial progressing cavity pumps?

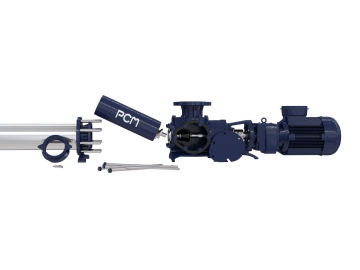

Key features

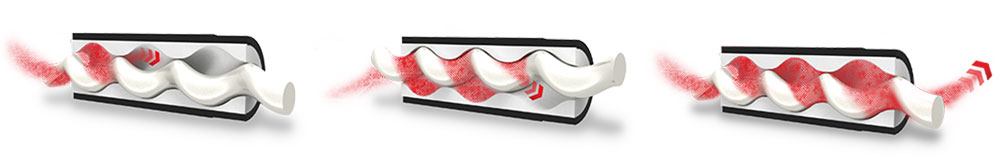

A type of rotary volumetric pump, progressive cavity pumps feature a turning helical rotor which rotates within the helical stator. Turning the rotor into the stator, the honeycomb travels in a spiral motion along the axis of the pump transferring the product from the suction to the pump discharge. These pumps are pulsation-free and are equipped to handle higher pressure (a maximum of 24 bars), this makes them well-suited for steady flow industry jobs regardless of liquid viscosity.

Pump principle

Industry sector applications

PCPs are found in various industries, such as pulp and paper factories where they aid in the process of paper production. They are also prevalently used in mining and minerals processing plants, as well as chemicals treatment plants and waste water treatment facilities, where cake pumps are integral to the recovery of dewatered sludge and other highly viscos fluids.

Recommended uses

Available in a range of materials, this pump technology is suited to handle corrosive, abrasive and/or fragile fluids. Proficient at dispersing a wide viscosity of liquids, PCPs are suitable for a host of substances, including corrosive and fragile liquids holding solids, whilst avoiding any damage to the product. These waste-reducing pumps have also evolved to cater for a demand in environmentally friendly handling of industrial waste.

Advantages

- Eco designed and low life cycle costs (LCC)

- Simplified maintenance

- Flow rate is proportional to running speed

- PCPs are reversible to suit your requirements

Performances

- Pressure: up to 40 bars (standard pump)

- Flowrate: from 3l/h to 250 m3/h

- Particle sizes: up to 48 mm