Pumping solutions for anaerobic digestion installations - Biogas

PCM for the treatment of liquid and viscous waste from anaerobic digestion plants.

Preserving our planet requires the use of more environmentally friendly energies. That's why PCM positions itself as the essential reference in providing pumping solutions for liquid and viscous waste..

PCM pumping technologies play a crucial role in your biogas production processes, optimizing the transfer of organic, plant, animal, and food waste.

PCM pumps cover a wide range of applications, ensuring the profitability and safety of your processes while delivering high performance, whether for the transfer of organic materials or digestates (liquids, viscous, dehydrated, fibrous, etc.).

PCM assists you at each stage of your anaerobic digestion process, whether it is for cogeneration, injection, or other applications..

PCM supplies pumps for every stage of your biogas process:

- Transfer of raw materials

- Feeding of digesters

- Recirculation of liquid digestate

- Transfer of digestate and/or raw materials to the sanitation system

- Transfer of digestate to the phase separator

- Evacuation of digestate

STEP 1

Storage and transfer of raw materials

Various raw materials are used for anaerobic digestion: animal by-products (pig and cattle slurry, pig, cattle, and poultry manure, fats, blood, bones...), crop residues (potato, corn, and cereal pulps, rapeseed meal...), abattoir waste (intestinal contents, brewery waste, flotation sludge, abattoir fats, molasses...), municipal waste (used fats, sewage treatment plant sludge, household organic waste, lawn clippings, sewage treatment plant fats...), food waste (expired supermarket products, restaurant and cafeteria waste...), etc. These products have high dry matter content (>40%) and can be abrasive.

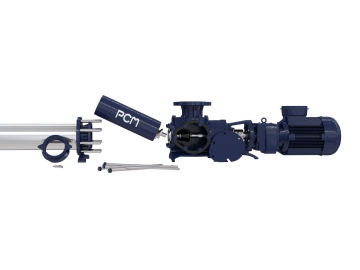

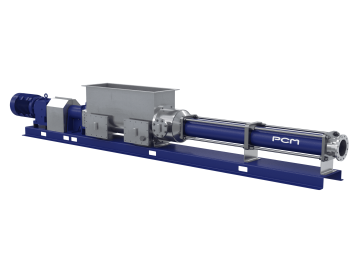

For effective pumping, progressive cavity pumps are equipped with Archimedean screws.

STEP 2

Feeding the digesters

Progressive cavity pumps and/or peristaltic pumps feed organic materials into the digesters to produce gas.

The choice of pumping solution is crucial; it must specifically suit the pumped fluid, its viscosity, and the size of particles present in it.

STEP 3

Recirculation

Progressive cavity pumps are used to facilitate the filling and transfer of organic matter to the digesters without clogging the pumps via a digestate recirculation circuit.

STEP 4

Hygienization

Depending on the raw materials used, regulations require pasteurization (hygienization), as for some animal by-products. In health regulations, the general principle is to hygienize upstream of digestion.

In this hygienization process, pumps transfer the organic matters to be hygienized from their storage area to the hygienization tank or digester.

STEP 5

Transfer of digestate

Once fermentation is complete, organic materials have been completely digested, and the substrate (digestate) has become liquid, low-viscosity, and low in particles.

Progressive cavity pumps will be used to transfer the liquid digestate from the digester to the phase separator for filtration.

STEP 6

Phase separation

A phase separator filters the digestate, separating solid residues from liquids to facilitate the storage of solid residues and spreading of liquid digestate.

STEP 7

Evacuation of digestate

The liquid digestate is evacuated and transported to agricultural fields, sometimes over several kilometers.

Progressive cavity pumps are effective in overcoming head losses and increasing internal pressure, especially over long distances.

Why Choose PCM?

PCM is committed to improving the efficiency of your anaerobic digestion processes, ensuring you:

- Long equipment and spare parts lifespan

- Reduced costly production downtime for your business

- Pump ranges perfectly suited for each stage of the process

- Pumping solutions adapted to abrasive fluid transfer, significantly reducing maintenance costs compared to lobe pump technologies

- Flexibility for an easy integration of our solutions into your industrial process

- Globally recognized robust and reliable products

- Complete and responsive after-sales service

- Commitment to ISO 14001 and Eco-design

- Patented products compliant with high-quality standards

Explore our industry catalogue here to find the solution that meets your specific needs for your anaerobic digestion plant.