Filling systems

Freedom to be creative: put ideas into production

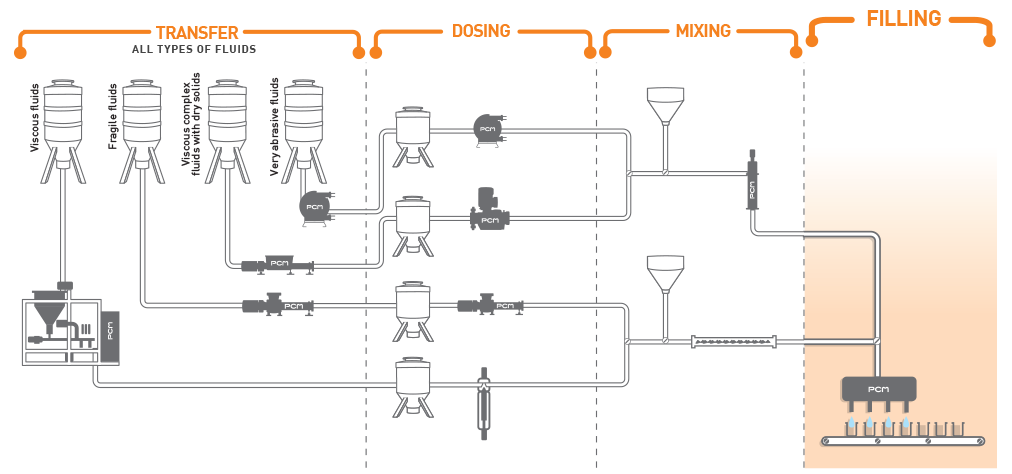

The creation of innovative food products relies on an efficient filling solution that is able to meet the complexity of mixing, recipes and conditioning techniques.

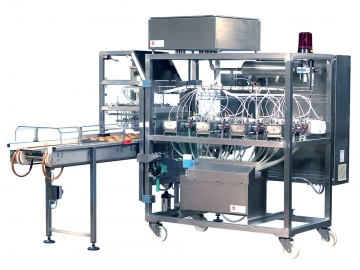

Nowadays, the creativity regarding containers and the diversity of textures seem limitless. PCM filling systems are designed to provide versatility and accuracy required for these operations, which can be very critical.

Benefits of PCM filling systems for filling applications

Dosys™ pump technology sits at the heart of all PCM filling systems. Invented by PCM, it makes it feasible to replace wasteful fluid transfer pumps with highly accurate and efficient inline injection.

Protect fragile ingredients

At the moment in your production process when the value of the final product is at the highest, the gentle pumping action of PCM filling systems handles your valuable ingredients with a maximum amount of care. Moreover, all PCM Filling systems comply with the strictest hygiene requirements and can be cleaned in place (CIP).

Powerful versatility

Every PCM filling system is designed to provide maximum volumetric flexibility. In other words, not only can you fill containers of all shapes and sizes, you can also vary the filling volume from one cycle to the next. Versatility extends to its compatibility with a multitude of filling ingredients, from liquid flavourings to viscous jams, from sticky toffee to semi-solid sauces. Finally, PCM filling systems integrate easily with your production line and packaging equipment, thanks to their modular design.